Featured

A ribbon of light

Anna Moldenhauer: How did the collaboration with Ambright come about?

Simon Busse: I’ve known Volker Scheuba (Head of Marketing at Ambright GmbH) for some time. Thanks to him I was able to visit the company’s production plant and we started our creative collaboration. In the space of just one year we were able to develop a luminaire and get it ready for launch. Up to this point, Ambright had exclusively produced individually manufactured luminaires for B2B customers with its patented printed-light approach. What we present now is the first series luminaire, "PARIS".

What made Ambright decide on this new option?

Simon Busse: The customized projects with “SparkShapes” involve a lot of planning and require close consultation between the architects and light planners, on the one hand, and Ambright’s own design team, on the other. Now, with the “Master Series” Ambright is set like to branch out into developing luminaire archetypes that can be produced in series and can be scaled up, enabling a swift response to different interior architecture requirements.

Is the “PARIS” suspension luminaire already on the shelves in stores?

Simon Busse: "PARIS" will be available from August 2023. However, since the market launch of a series product is different from the lighting solutions that are only produced once, we are just fine-tuning the processes one last time - be it the most sustainable packaging possible or the point of sale. These steps were not previously necessary for Ambright in its approach.

On your website you write that you are fascinated by aesthetic precision, a sense for technology and a passion for experimenting. To what extent did you see these aspects echoed in your collaboration with Ambright?

Simon Busse: What fascinated me about Ambright was the very different approach to the production of a luminaire, that they think "out of the box". I find the patented "light printing", the precision and that all processes can be done with a single machine fascinating. Other manufacturers have 20 different production processes and Ambright manages to produce a luminaire with only one machine. In addition, founder and CEO Dr.-Ing. Florian Ilchmann and his team have a great deal of expertise in lighting technology - this was also the basis for the development of the SparkShapes and the more than 10-year collaboration with Siemens Healtineers, which enabled Ambright to start in a market with the highest quality requirements, medical technology. Engineering know-how meets design, a wonderful combination.

Was there an aspect you would like to alter for Ambright?

Simon Busse: Initially, Ambright’s luminaires were realized in a very two-dimensional way and it appealed to me to create designs in a more three-dimensional way, whose elements can be placed both vertically but also horizontally.

The “PARIS” pendant luminaire consists of two illuminated layers that run perpendicular to each other and can be controlled individually. Where did the inspiration for that come from?

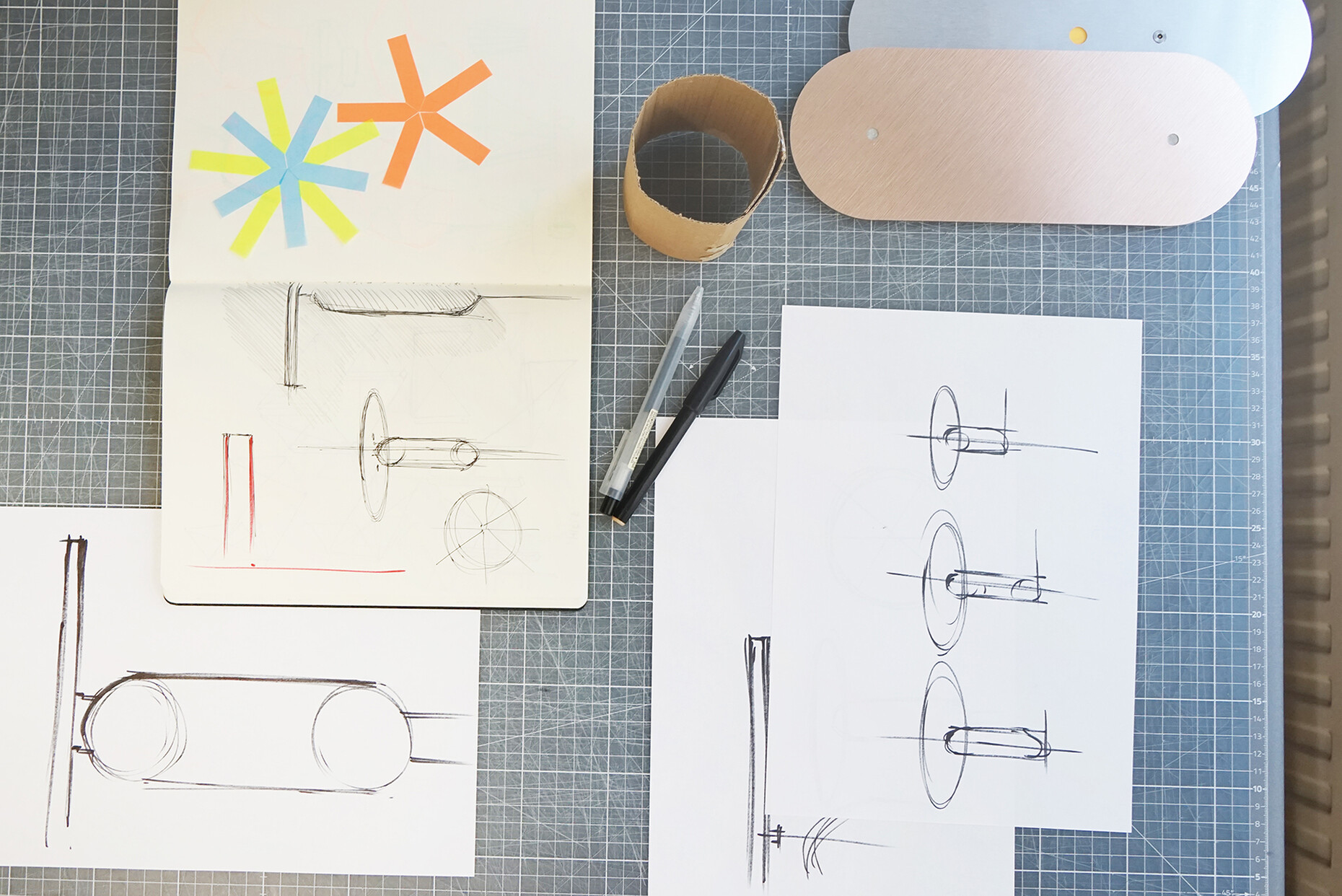

Simon Busse: The trademark of SparkShapes is the homogeneous illuminated edge and the idea was to have it appear like a line within the context of a three- dimensional structure. By alternating horizontal and vertical elements this illuminated edge now contributes to the sculptural appearance of “PARIS”. The surfaces are slender and, thanks to the special surface coating, are also used as a gentle reflector. In addition, the shape should look a little archetypal - despite the abstract surfaces, you can see in it a traditional pendant lamp.

Was there an idea you were able to realize for the first time thanks to the SparkShapes technology?

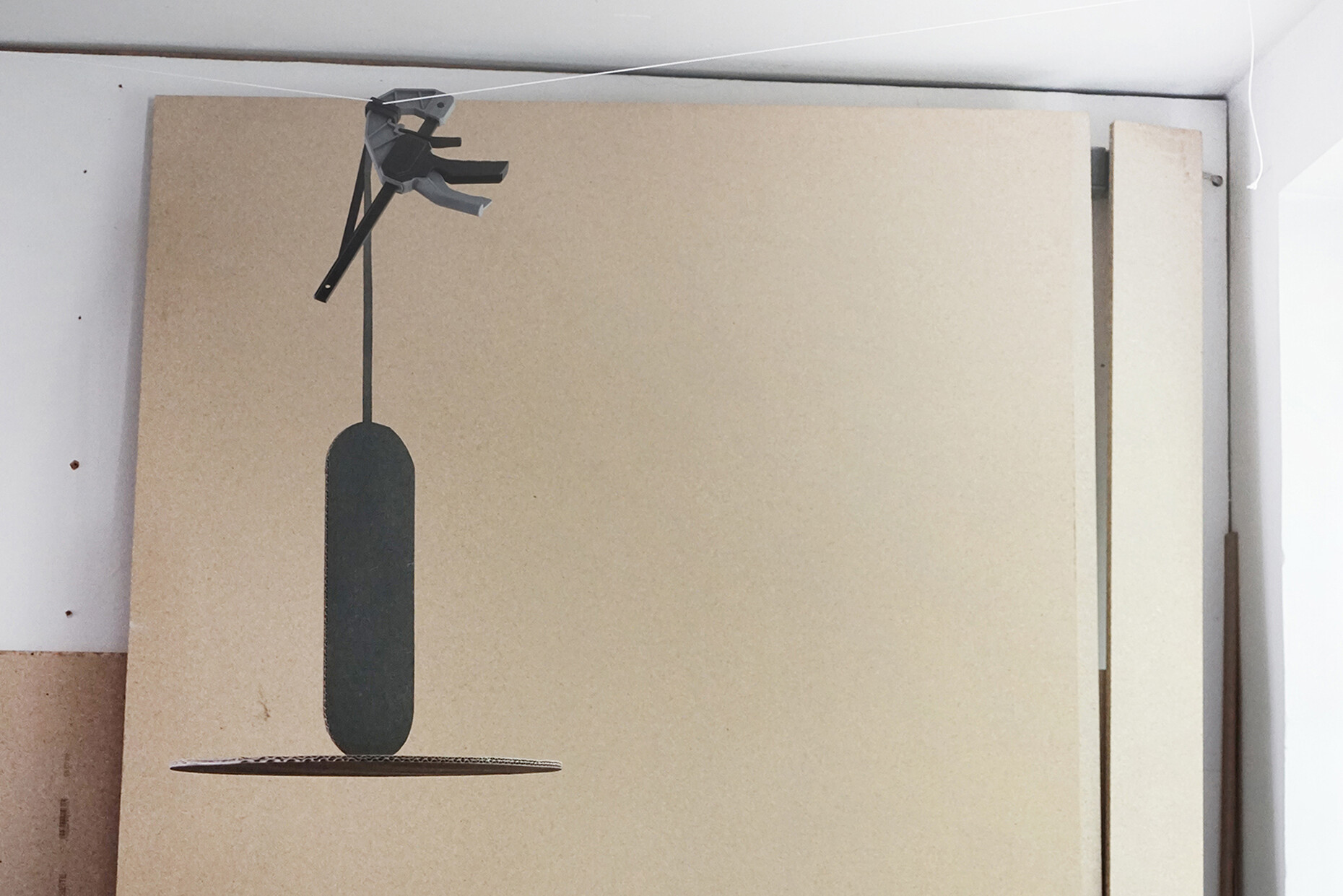

Simon Busse: The transfer from the sketch to the product is perfect with “PARIS”. With SparkShapes the lines of a drawing can be realized without needing to add an additional volume.

Are you saying that with SparkShapes it’s possible to bring a minimalist sketch to life on a 1:1 basis?

Simon Busse: Precisely, because the subsequent production is not a problem as the material is defined from the start. For the first time, light becomes, so to speak, a material with which to design.

“PARIS” was showcased at this year’s Salone del Mobile in Milan in cooperation with furniture brand Yomei. What feedback did you get from visitors for the design?

Simon Busse: Although we were only a small cog in this big wheel, I was able to talk to a lot of visitors and the positive response even before the market launch surprised us all. With “PARIS” we were able to challenge the viewing habits of visitors as its structure is more minimalist and delicate than one is otherwise accustomed to for such structures.

What are the next joint steps with Ambright?

Simon Busse: Gratifyingly, we have already received inquiries from retail partners who would like to include the luminaire in their range even before the official sales launch. As it takes up so little space, in terms of logistics it only requires very flat packaging. And with regard to the technology of Ambright we are currently pushing the borders of what is now possible which is very exciting.

You completed both a craftsmanship training and industrial design studies. How do these two aspects shape your creative work?

Simon Busse: For me, many projects begin via the material. It’s often the case that companies overlook a material’s diverse uses in processing; for example, felt was used for a long time as an insulating material in car boots but not for furniture until its acoustic properties were recognized. It was above all my training at the Design Academy in Eindhoven that made me more acutely aware of this as the various creative areas there have a very interdisciplinary approach. Rather than starting with a concept it often makes more sense in creative projects to begin with an unworked material and then develop the process from this point. I also enjoyed the approach at the Stuttgart State Academy of Art and Design, where we designed 1:1 prototypes focusing strongly on the material and its manufacturing properties. Creative freedom often comes down to enabling alternatives in the design process.

You advise companies in design management and have various teaching appointments including at the Chinese Academy of Art (CAA) in Hangzhou. What do you feel is important to pass on to students about your profession and design?

Simon Busse: To my mind, the best thing you can pass on to students is to have confidence in your particular topic. And in order to find out which creative area you would like to focus on it’s helpful to create a large pool of inspiration – be this in the form of visual impressions or through communication with others.