SUSTAINABILITY

Autonomous furniture

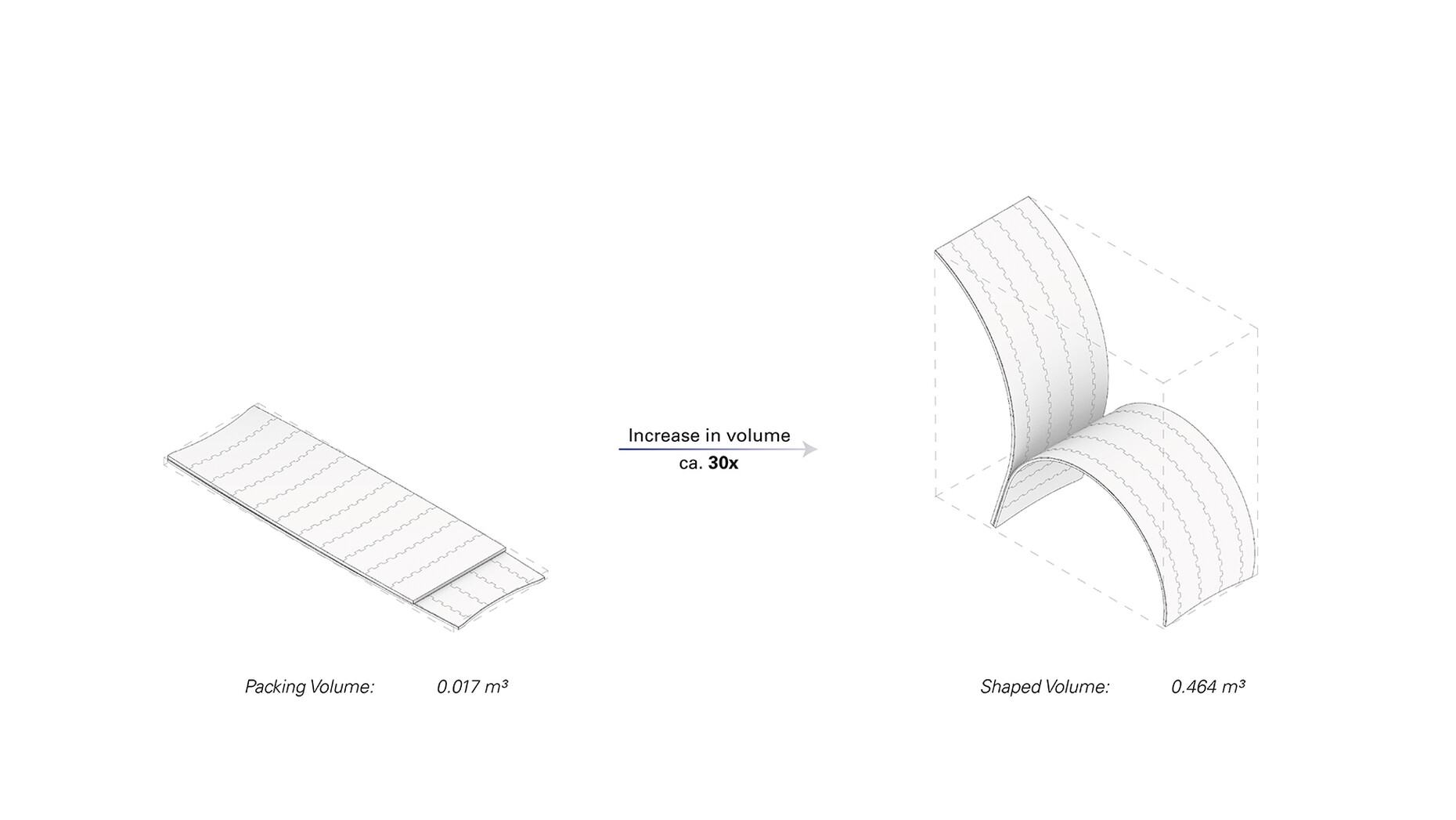

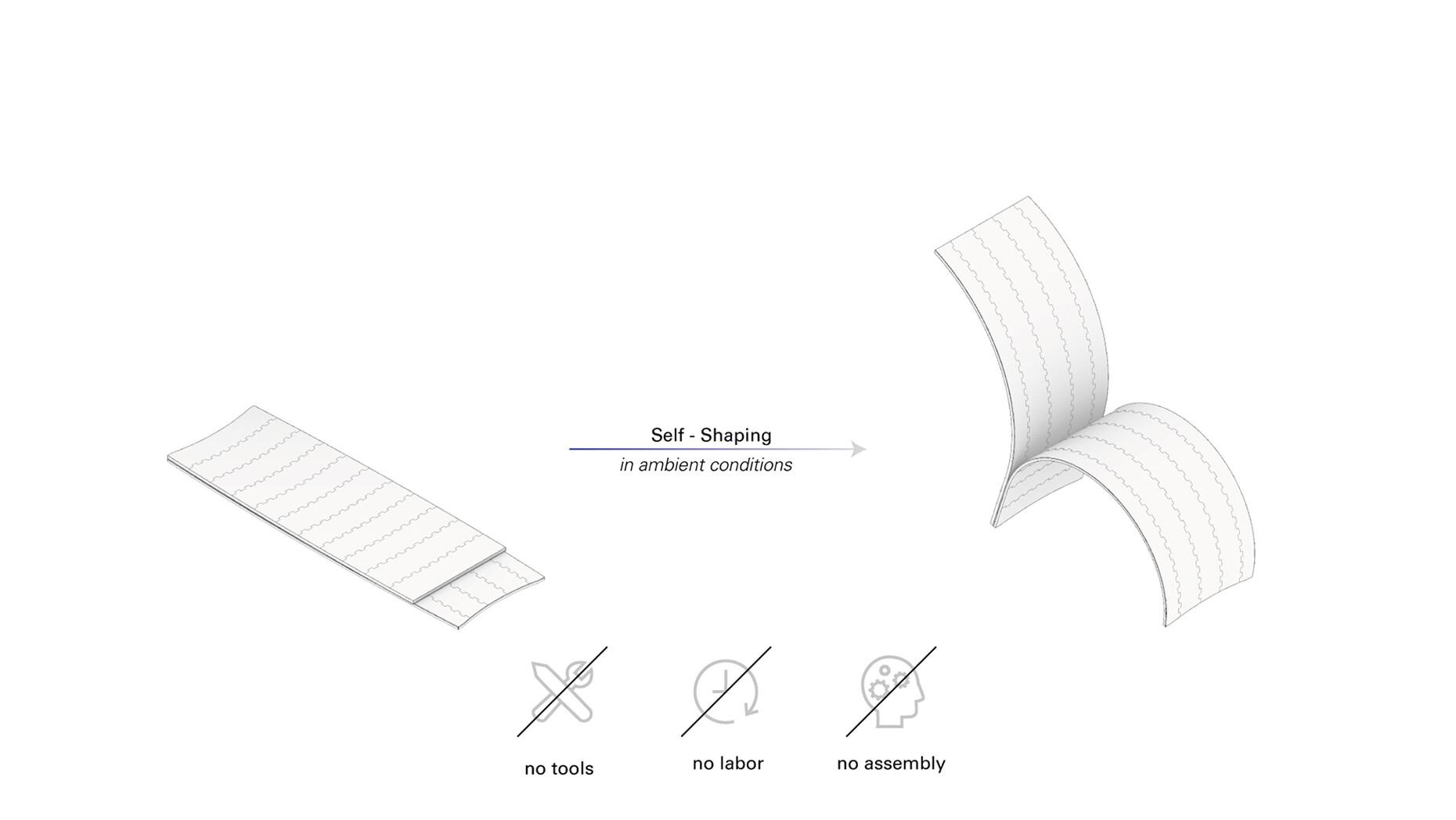

A chair made of wood that is delivered flat-packed but does not need to be assembled to achieve its final shape – how is that supposed to work? To this end, a team from the ICD Institute for Computer-Based Design and Construction Manufacturing at the University of Stuttgart, in collaboration with the Technical University of Dresden and ETH Zurich, has researched a process found in nature: the deformation of wood through hygroscopic shrinkage. When the cell walls of the material dry after harvesting, they contract and the uniform curvature of the wood is created. "HygroShape" is thus the first concept for self-forming furniture. The project builds on the knowledge gained by scientists from Stuttgart universities and ETH Zurich in the course of constructing the "Urbach Tower", the world's first built object made of self-forming wood. In 2019, the 14-metre-high experimental building was created, which now serves as a landmark and vantage point for the town of Urbach in Baden-Württemberg. "The idea for self-forming furniture emerged from this project," says Laura Kiesewetter from the ICD at the University of Stuttgart. Depending on the layer thickness and taking into account the fibre orientation in the material, the arch shape could be controlled very well, Kiesewetter continues. The dynamic design is based on a calculation of the shrinkage process and a determination of the moisture content of the multi-layered wooden components. By changing the parameters, a personalised design would also be possible. In general, the technology is not dependent on a specific type of wood; the team has used maple, beech, ash, spruce and cherry wood for their research so far.

The first pieces of furniture are "H1" and "H2", a lounge chair and a chaise lounge made of FSC-certified maple wood arranged in thin double layers. However, there is no need to worry that the shapes will change with a slight variation in the interior temperature. The thickness of the material also provides a certain buffer effect. To bring the slender surfaces and elegant curves back to a flat state, a sustained soaking would be necessary. Laura Kiesewetter and Dr.-Ing. Dylan Wood have now founded "hylo tech" for the leap to market maturity and further development of the technology, also with a view to lightweight, load-bearing construction elements. All of the spin-off company's products are bio-based, bio-moulded and could thus contribute to more resource and manufacturing efficiency.