Quiet heroes

"We have a long-term goal to decarbonise our operations and we have been working hard to find solutions that will help us achieve this. This new pan-European partnership not only helps us on our way to net-zero but is also a clear step forward for the industry as a whole," says Albert Magrans, CEO of Roca Group. Together with Keramischer Ofenbau GmbH from Hildesheim, the family-run company recently presented the result of their joint research in Gmunden: The world's first electric tunnel kiln for sanitary ceramics. The facility in Upper Austria is set to become the globally first CO2-free for sanitary products this year. At the same time, the production site was equipped with a solar system to generate the required electricity from renewable sources. The furnace's processes are thus decarbonised and automated for maximum efficiency – a pioneering development for which the Group has already filed a patent application.

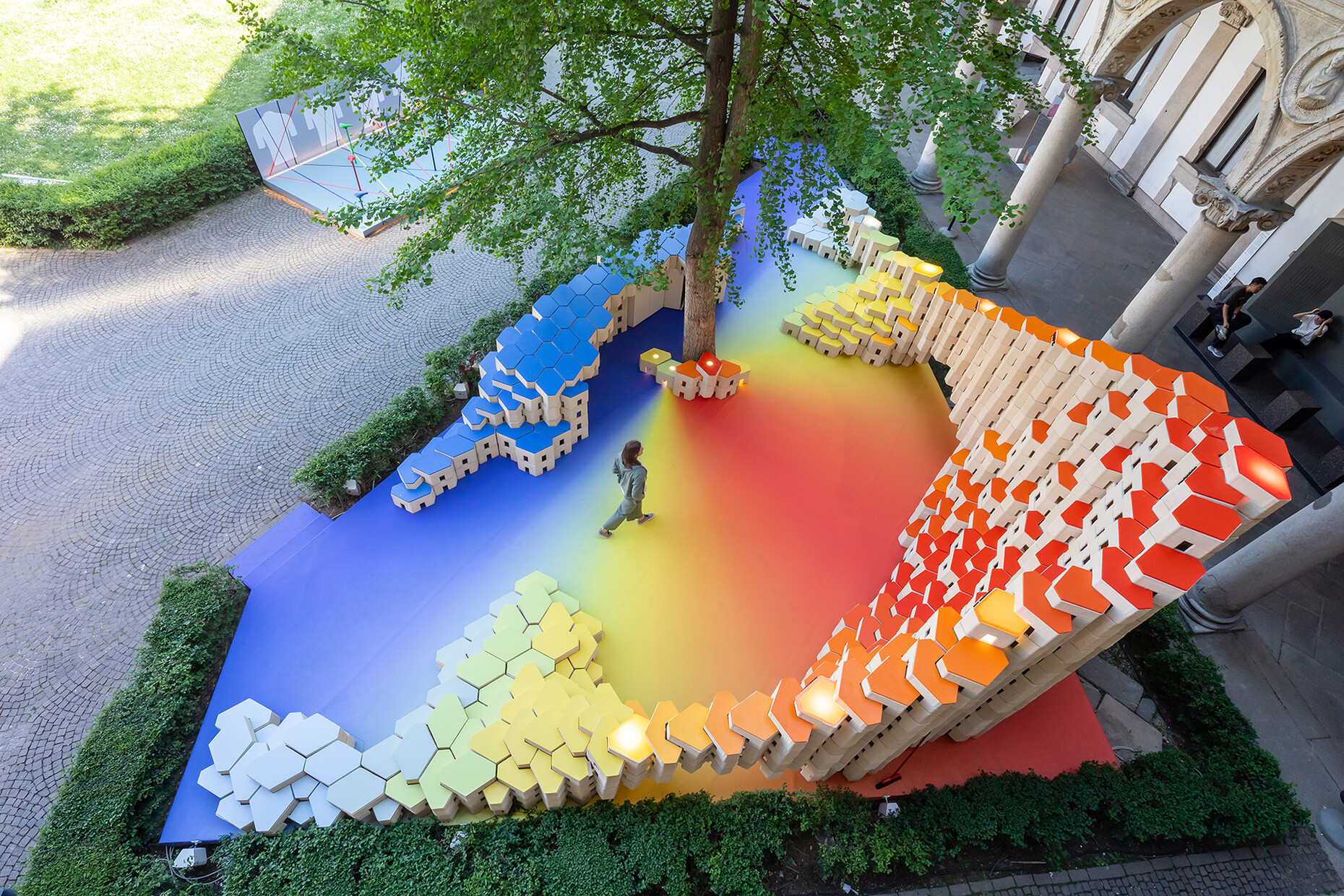

At this year’s Milan Design Week, Roca together with Mario Cucinella Architects visualized the positive effect decarbonization in the ceramics industry has on the environment with an installation entitled “Sparking Change”: In the inner courtyard at the University of Milan, a 4.5-meter-high scenographic world was created consisting of 1,200 3D-printed modular elements made of recycled ceramics. The nuanced coloring and curved structures served as visual metaphors for the progressive operating temperatures in the firing process. Each of the blocks featured details showing what temperatures are required in that specific production phase in order to guarantee ceramic products of the highest quality. After the end of the installation, the elements can be reassembled as street furniture or pavilions. Alongside the physical exhibits, Roca expanded the voyage of discovery into the sustainable production process in the form of Web-based Augmented Reality highlights. “’Sparking Change’ underscores Roca’s commitment to sustainability in a unique installation that shows how knowledge, experience, and technology have enabled Roca to develop the single largest innovation in this sector,” comments Marc Viardot, Roca Group's Marketing and Design Director.

The e-kiln technology is not just of relevance for the production of sanitary ceramics, a few technical adjustments, and the technology created can also be used to fire construction ceramics, such as bricks or pipes, and tableware. “This kiln is proof that innovation and progress really make a lot possible which in the first steps involved may initially seem inconceivable. Seen in that light, it’s a huge milestone,” concludes Axel Krause, Project Management and Development, Keramischer Ofenbau GmbH.