SALONE DEL MOBILE 2017

Salone, viewed critically 03: Business recycles

In the eye of the storm of new products swirling around at the Salone, it is not just the question of enduring design that pops up. The storm, and it lasts for a whole week, dims the eye for the counterpart to such design, namely sustainable, as recycled materials and their possible uses. Observe and act, i.e. aesthetics and ethics, a feel for beauty and a feeling of responsibility continue to find it hard to bond. This likewise applies to an approach to design that no longer focuses on the finished object, but the entire production process – and seeks to help shape it.

In this context, three things can be said: First, we consumers like to leave the ecological thinking to the politicians or delegate it to industry, in this case the furniture manufacturers. May others stop the flood of plastic and packaging waste. Second, we journalists and critics tend then to turn up our noses at this and take the side of aesthetics when once again a seat shell or a bench made of regenerative materials of recycled plastic gets presented. We respond no less skeptically when marketing departments use sustainability as a slogan with all their products and the companies wave their corresponding eco-certificates about. Third, we as consumer still underestimate how long it takes in a highly technological industry with its division of labor for proven modes of production that have been successful in the market to be changed. We simply don’t want to know that this requires alternative waster and goods cycles as well as considerable investments. In a nutshell: Furniture made of recycling materials still has a tough time of it, although the segment is playing an ever more important role. Not a few manufacturers have grasped this and are already using recycled materials. Two examples in this regard really caught our eye in Milan.

Eco-oh! and how to recycle plastic

Lest we kid ourselves, we Germans love to bask in the fact that we are world champions, not just in football, but in separating waste. What then happens to the collected materials remains largely hidden from sight. Yet, as a discussion on the booth of the “Eco-oh!” group at the Triennale shows, countries such as Belgium and the Netherlands have evidently got much further. While, or so we are told, in Germany only something like one third of the plastic waste gets recycled, with the remainder being combusted, Eco-oh! is already easily able to meet the new European recycling standard for household plastic waste that sets the target at 55 percent by the year 2025. Indeed, Eco-oh! can achieve a real materials recycling rate using a purely mechanical process – of as much as 97 percent.

It is hard to gauge at the spur of a moment whether the numbers are right. But one thing is for sure: much is underway in the industry. While we consumers find it hard to distinguish between PET, PE, PP and PVC plastics and simply stick shrink wrap, yoghurt cups and flower pots in the same bin, the severely soiled and mixed plastic waste can long since be perfectly separated and cleaned mechanically before being reprocessed into granulate from which new products can be made. Eco-oh! has plant tub surrounds and compost containers made of simple recycling materials in its lines, just as it offers hollow profiles and benches for gardens or urban spaces. It’s H-Bank for example, consists of finer, easily dyed material and relies on modules that simply get placed side to side. And the Altamira collection by artist François Blommaerts even boasts an extravagant design. What is more important than deciding whether the benches have a good design or not is the fact that a material has been developed that is available as mats and can be molded, something that will no doubt delight the one designer or other.

Really or how to recycle fabrics

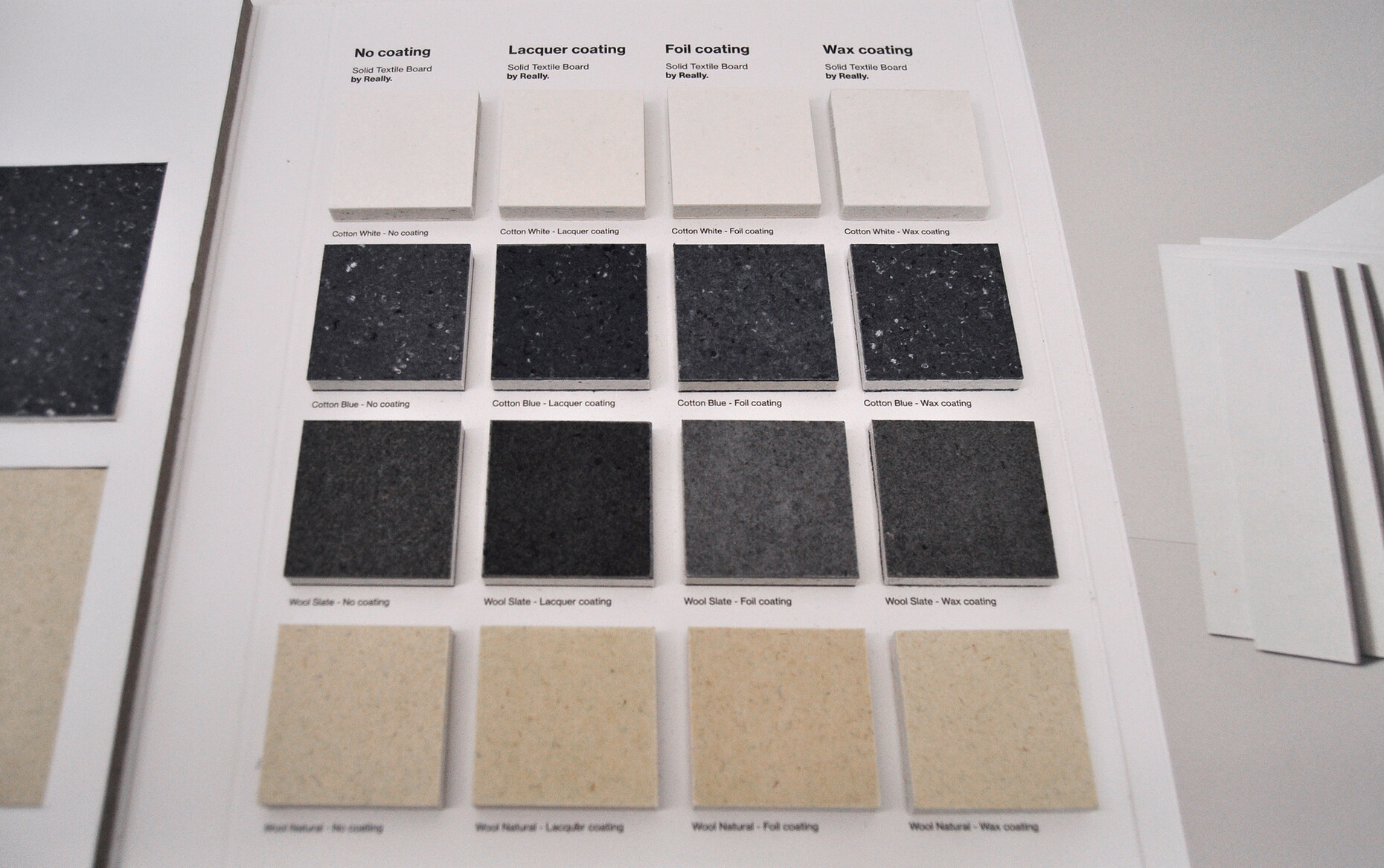

Another, highly promising project starts from industrial production processes, in this case fabrics. The company is called “Really” and was founded in 2013 by Wickie Meier Engström, Klaus Samsøe and Ole Smedegaard. Kvadrat has since acquired a 52-percent stake in the firm. Really focuses on upcycling cotton and wool waste that arises both in textile and fashion production, but also as old clothes in private homes. Really adds reversible binders to the textile fibers thus obtained to create a “Solid Textile Board”, a high-density construction panel that is an alternative to MDF panels for dry walls and can be used in furniture design, too. In Milan, Max Lamb and Christien Meindertsma presented some examples of the benches, tables or shelves you can make using it were. For in textiles, too, 95 percent of the used fabrics could be recycled, compared to the current level of only 25 percent.

It’s clear that we’re still in the early day of developing materials from recycling or upcycling waste. Designers who act responsibly in both ethic and aesthetic terms will no doubt soon be testing how viable they are. And then there’s the market, and us as buyers and consumers who do not wish to convince ourselves an some abstract level of the ecological necessity of such materials, but want to rave about actual products. The rest is styling, and there’s plenty of that running around as it is.