Flexible light

Anna Moldenhauer: Prof. Leo, you have been researching organic semiconductors since 1993, what is your motivation for this topic?

Prof. Karl Leo: I am a physicist and basic researcher. That's why I didn't necessarily want to design a product in the first place. My drive came more from curiosity to better understand organic semiconductors, because they have completely different properties than classical semiconductors. The application of OLEDs and solar cells came about en passant.

With the company Novaled, which has since been taken over by Samsung, you were able to very successfully link research and the market, which does not happen often in physics. What was important to you in the process?

Prof. Karl Leo: From basic research, we saw that our findings had commercial relevance and basically founded the company Novalis quite naively. Despite a bumpy start, the project has developed very well - our technology is now integrated internationally in billions of electronic products such as mobile phones or televisions. That doesn't happen so often in physics. It requires the right topic, because there are many areas in research that have no immediate application relevance. In addition, the researchers must have an interest in the area of application. But that was always the case with my team and that's why we approached industry with our findings.

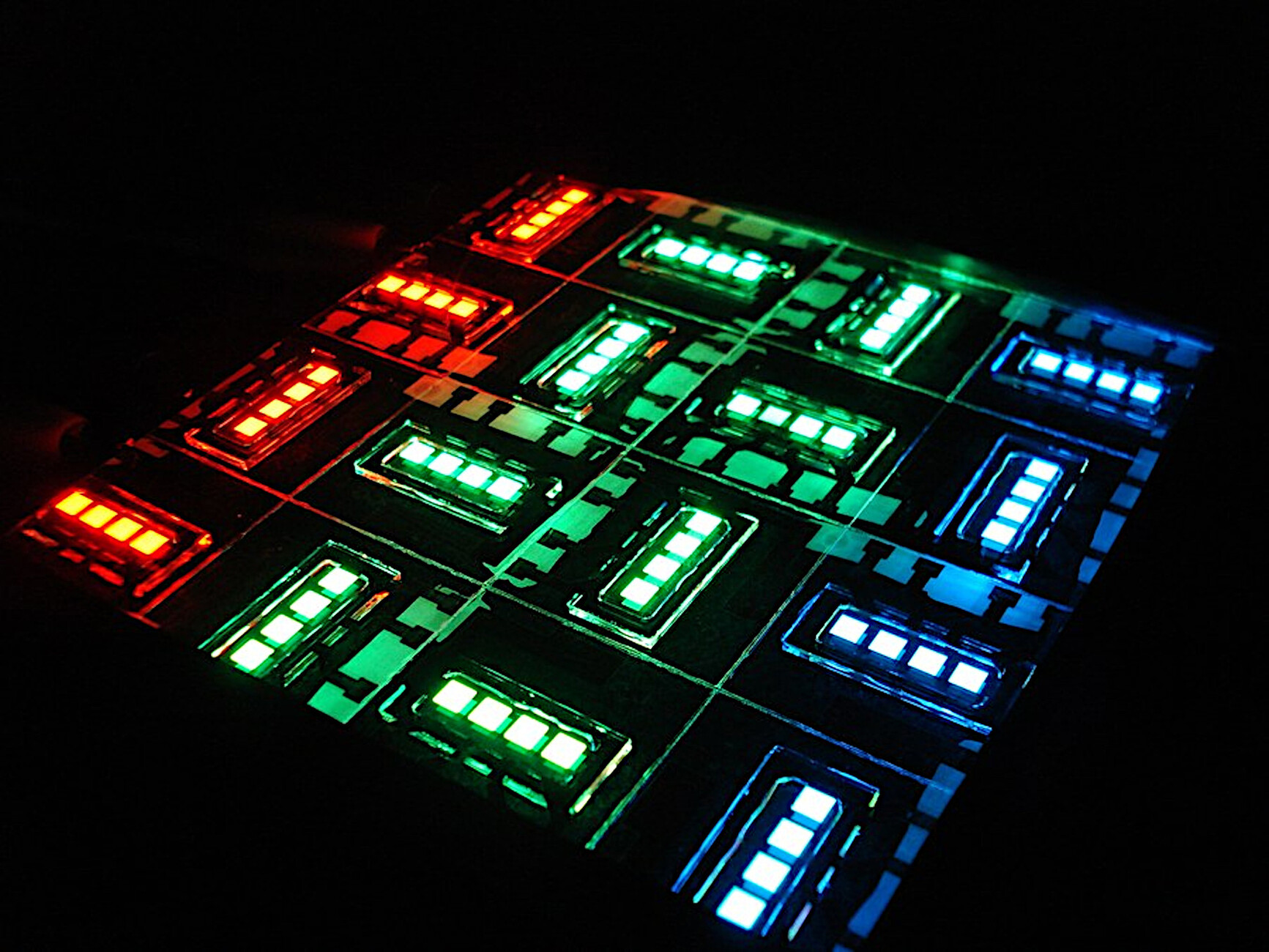

You have developed an OLED technology that provides more picture brightness, higher colour resolution and better energy efficiency. How did you achieve that?

Prof. Karl Leo: The decisive point we contributed was the so-called doping. This is a simple effect, because a semiconductor is a poorly conducting material in its pure state. By adding dopants, though, you can greatly increase this conductivity. This was already known about silicon and has been used for decades. In the context of OLED research, it has been viewed rather critically up to now. In research, we found out that this process massively improves the efficiency of the components.

Many colleagues rather laughed at your research at the end of the 1990s. Why was that?

Prof. Karl Leo: I was a newcomer to semiconductor research - and when you come from the outside, you sometimes find approaches to solutions that established researchers have rejected from the outset. There was also little interest from German industry. In the end, it was Korean industry that supported us and with whom we were able to lead our research to success.

What is still missing for OLEDs to become the standard in the lighting industry?

Prof. Karl Leo: A very important aspect is the cost, which is currently still too high. In addition, OLED technology as an area light source requires a certain geometric size in contrast to LEDs in order to achieve a desired light flux. The LED luminaires are basically only so cheap because you have a tiny chip, but it produces a large light flux. The second factor is that the lighting industry largely assumes point sources, but the OLED is a flexible area source and is different in both design and use. The OLED cannot be plugged into an existing lampholder as a new light source; it requires new concepts.

Do you think that OLEDs could replace LEDs in the long term?

Prof. Karl Leo: No, I don't think so. In everyday life, you simply need point light sources more often than not, and OLEDs can't do that. In automotive lighting, for example, OLEDs are already being used in the rear lights, because a flat effect is required there. In front lights, on the other hand, a controllable beam of light must be produced, and the OLED is the wrong tool for this. Nevertheless, the efficiencies are continuously increasing and I think that the very best LEDs will soon not be far from saturation with OLEDs.

OLED offers a natural, glare-free light. Would an HCL application also be conceivable?

Prof. Karl Leo: That is an important aspect. The quality of OLED light is essentially softer and broader than LED spectra, which plays an important role for lighting. We have already done some work on this and shown that even a flat light source can reproduce a large spectrum.

OLEDs are energy-efficient, recyclable and free of toxic substances. To what extent would you say the technology is more sustainable holistically?

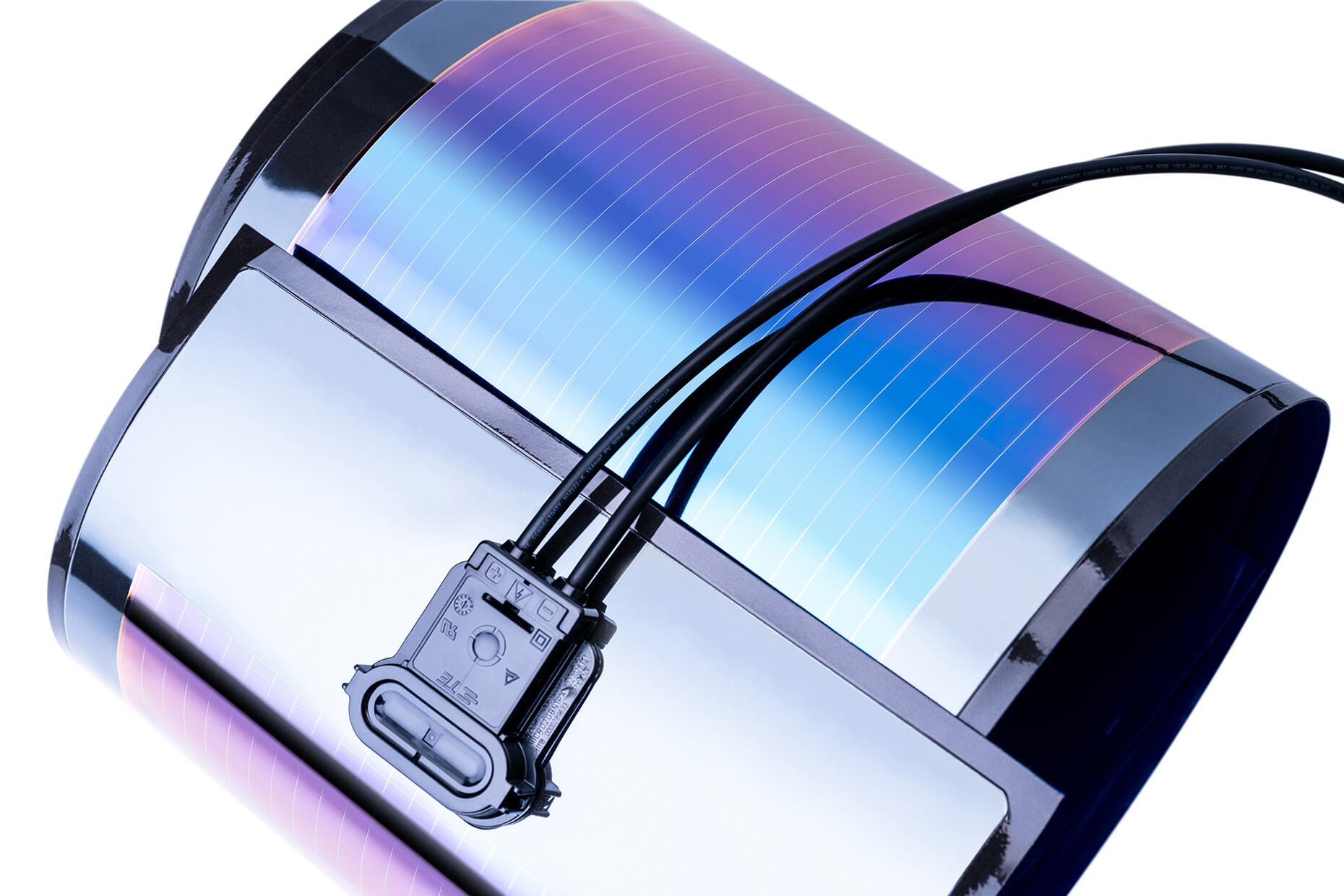

Prof. Karl Leo: The OLED is a natural light source. If you look at the structure of the OLED from several layers, the actual organic layer is rather the smaller part. The crucial aspect is the substrate, which is currently mostly glass, but could also be a recycled or recyclable plastic film. Very little material is needed to build an OLED because the layers are very thin. All components can also be easily recycled.

The University of Minnesota recently used a 3-D printer to produce a flexible OLED display and would now like to make this possible for non-professionals as well. Are you also researching in the field of 3-D printing?

Prof. Karl Leo: We have mainly worked on a vacuum process in which the organic materials are evaporated under temperature, close to the industry standard. Of course, there is an interest in printing OLEDs and other organic devices, because this process offers more flexibility in terms of time and space. However, this is at the expense of the lifetime of the devices. I think it will be possible to print OLEDs in the long term, but the idea that you can quickly pull an OLED out of your in-house printer is still very far from reality.

Quality control is then also likely to be difficult.

Prof. Karl Leo: Yes, that is a very important aspect! The organic materials are very sensitive to humidity and have to be encapsulated. That is not a trivial process.

OLEDs react sensitively to oxygen as well as humidity. In your view, is there still room for improvement in the protection of organic elements?

Prof. Karl Leo: A lot has already happened. When we started, glass encapsulation was the only way. Today, thin-film systems are much better and displays are regularly made of plastic film. For the lighting, however, the costs would still have to be reduced.

You are also researching in the field of solar cells, could the two technologies be linked?

Prof. Karl Leo: We have been researching this for several years: a transparent solar cell that generates energy during the day and in the evening, thanks to the OLED, you could operate it as a light source that simulates daylight. From a purely physical point of view, this is possible, but it is also a question of cost. In the field of lighting, the combination of solar cell and OLED would certainly be a very attractive application.

Your research has made an international impact. Why did you stay at the Technische Universität Dresden?

Prof. Karl Leo: I see myself as a basic researcher and I am in very good hands at the university. Especially at TU Dresden, because the Dresden region is the leading location in Europe for semiconductor electronics. In addition, the support for research from the city, the state and the EU is not so easy to beat.

For your research on optimising OLED technology, you received numerous prizes, especially last year, including the European Inventor of the Year Award 2021 in the "Lifetime Achievement" category and the Jan Rajchman Award of the Society for Information Display (SID) as the first German prize winner. What are you currently working on?

Prof. Karl Leo: We are working on different projects and it would be desirable for the whole team to be awarded these prizes instead of a single person. Currently, we are researching very intensively on several major topics: on optical sensors and on an organic transistor in the field of polymer electronics. We are also working with medical scientists - for example, to develop an organic component that can measure pressure for a while after operations in the middle ear. This gelatine snippet would only be about two millimetres in size and would remain in the ear to monitor bodily functions. The data could be read out with appropriate electronics and after the end of the follow-up, the body itself degrades the bioelectronic chip. Research can thus help on many levels.