YOUNG TALENTS

Successful experiment

Julia Hauch: Your design should fit naturally into everyday life and surprise at the same time – how do you manage this balancing act?

Steven Dahlinger: I avoid short-lived effects or overly stylised forms, focusing instead on balanced proportions, precise details and an inner logic that lends an object permanence. Often, the actual special feature only becomes apparent at second glance or when the object is used. This may be a particular function, an unusual choice of material or a specific construction. In the case of the ‘Nesting’ sofa, for example, the reclining function only appears when it is needed and disappears when the sofa is folded up.

The ‘Nesting’ collection was released last year by Wagner Living. It was a very successful project that was realised while you were still a student. How did that come about?

Steven Dahlinger: The designs were created in the context of our seminar ‘workspace in progress’ – an examination of the future of our working environments. I was particularly interested in the relationship between openness and privacy. Although there are many pieces of furniture designed for personal retreat or separation, they are often very rigid and not particularly flexible. I liked the idea of a piece of furniture that offers space for retreat when needed, but does not impose itself. Solving this with a foldable, double backrest was also an exciting design challenge. Peter Wagner was very enthusiastic about my 1:1 mock-up of the ‘Nesting’ sofa at the time. The idea came at the right time.

What experiences did you take with you from this collaboration?

Steven Dahlinger: It is important to approach a collaboration with an open mind. An idea often changes several times before it reaches its final version – and that's a good thing. A certain degree of pragmatism and flexibility is required, as long as you don't lose sight of the essentials. As a designer, you are not only a creator, but also a project manager. A good idea alone is not enough – manufacturing, transport, marketing and sales also play a role.

You studied industrial design at the University of Applied Arts in Vienna and graduated under Stefan Diez. What has had a lasting impact on you?

Steven Dahlinger: I learned a lot from Stefan. Above all, how crucial well-resolved details are and how important it is to consider the bigger picture when designing, right down to business models. He has a keen sense of what a design really needs, and he encouraged me to approach manufacturers. Overall, at the University of Applied Arts, I learned to approach topics with courage, not to give up so quickly, and to push for more sustainable and circular design.

You usually approach your projects in a very experimental way.

Steven Dahlinger: I am interested in creating aesthetics and form from the material and its properties. A good example of this is my table ‘Bow’, whose shape was created by twisting the legs and fixing them in the maximum tension state. With ‘Tens’, I also explored the relationship between the substructure and material tension in numerous experiments. I really enjoy this practical process.

Your table ‘Tens’ was created as part of your thesis, which deals with the potential of self-supporting textiles. How did you come up with this topic?

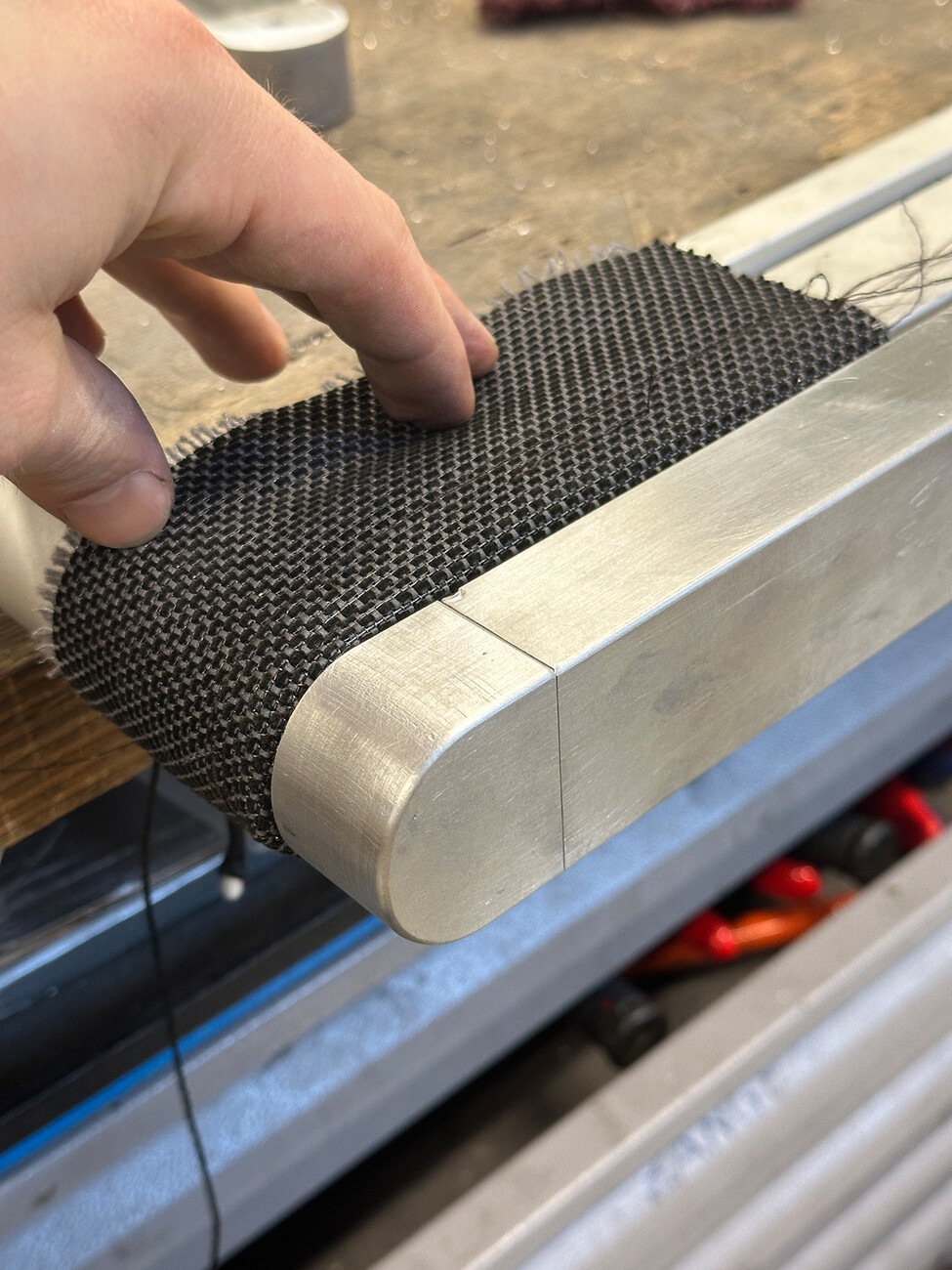

Steven Dahlinger: ‘Tens’ arose from an examination of the materiality of workspaces and storage areas, with a focus on lightweight construction, sustainability and circular materials. Since we are surrounded by huge areas of complex composite materials every day, I wanted to search for lighter, more easily separable and, above all, circular alternatives. The concrete idea then took shape during my visit to Orgatec. There I met Krall+Roth and their patented material ‘Shrinx’. Originally developed for lighter and foam-free upholstery, the textile shrinks when exposed to heat between 80 and 120 degrees Celsius, creating high tension and becoming self-supporting. I was fascinated by the idea of transferring this material from its usual context into something completely new.

The project is initially a design study – what happens next?

Steven Dahlinger: I still see great potential in the design logic of tensioned textile surfaces, which needs to be explored further. The next important step will be to test ‘Tens’ over a longer period of time in real everyday life in order to gather practical experience and feedback. For serial production, I would find a collapsible frame interesting to facilitate transport and logistics. I am also playing with ideas for a height-adjustable single workstation or a foldable version. I am also working on transferring the principles to other types of furniture, such as shelving systems. This makes me all the more excited about a possible collaboration with a manufacturer who is interested in further developing the project together.

Where does your passion for design come from?

Steven Dahlinger: Design in all its facets has always fascinated me. As a child, I was enthusiastic about archaeology, about making past worlds visible again. Later, I wanted to become a painter, then I was drawn to animated films and video games, where you can invent entire universes. I am fascinated by the emotional impact that spaces and objects can have on us. At the same time, I always wanted to understand how things are created, whether by hand or industrially. The experience of designing something and then having it physically in front of me is still one of my greatest motivations today.

You initially studied political science – how does that help you today as an industrial designer?

Steven Dahlinger: My studies definitely sharpened my awareness of the complex social, political and, above all, economic context of design.

It is generally quite rare for young talents to be given the opportunity to prove themselves at large companies. What advice would you give your colleagues?

Steven Dahlinger: At first, you have incredible respect for approaching companies. But you forget that on the other end, there are often highly motivated and friendly people who are waiting for the right ideas and looking to further develop their products. Personal contact at trade fairs and events is also extremely helpful. What definitely scores points is presenting your idea as clearly as possible – whether through a prototype or great visualisations.

What are you currently working on?

Steven Dahlinger: I am currently working on further developing ‘Tens’ and on a lighting design that has been on my mind for quite some time. I'm also expanding my digital skills. I'm interested in how the integration of AI tools will change the design process, for better or for worse. And I'm currently setting the course for my professional future: there are a few projects I'd like to pursue independently, but I can also imagine working in a design studio to gain more experience and exchange ideas.