Techtextil

“Sometimes industry is further advanced than we architects realize”

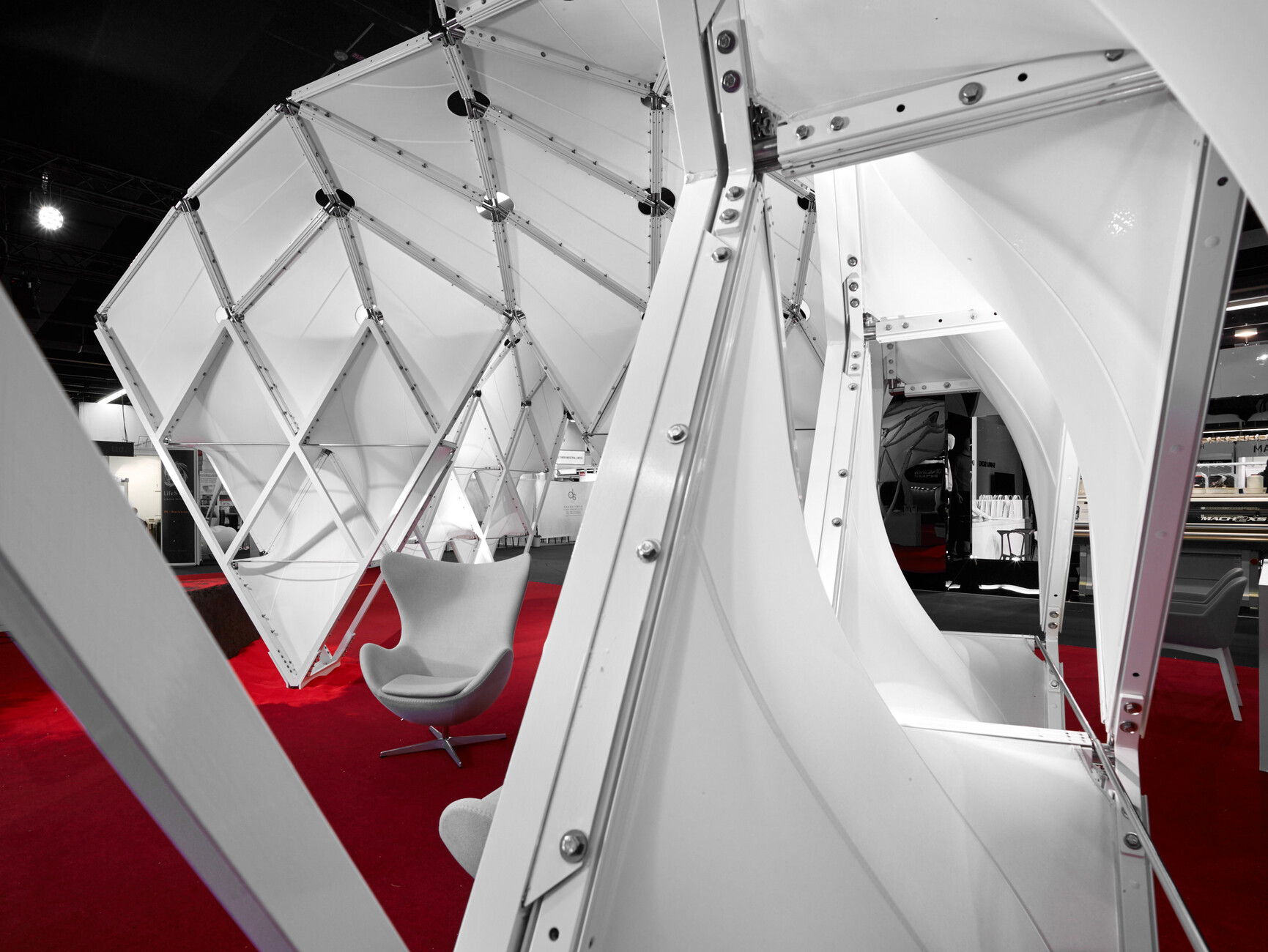

Together with German textile specialists MDT-tex Amsterdam’s UN Studio architecture company and its founder Ben van Berkel have been intensively exploring applications for technical textiles in architecture. After an eye-catching pavilion for the Amsterdam Light Festival 2016 a successor is now being presented at the Techtextil trade fair in Frankfurt. It boasts two interconnected space beneath a vaulted roof made of 3D textile elements and metal profiles. The textile elements are made of PTFE, a material that came to fame under the name of “Teflon”. Fabian Peters spoke to Ben van Berkel about his interest in textile building materials.

Fabian Peters: Together with German makers MDT-tex you have realized a pavilion for the Techtextil trade fair with an outer skin consisting entirely of PTFE. What so fascinated you about textile architecture?

Ben van Berkel: At UN Studio we are conducting intensive research and are thrilled by the collaboration with MDT-tex. We’re very interested in new materials, in a sustainable and healthy architecture. What fascinated me about textile architecture and in particular about PTFE fabric is its durability, its self-cleaning properties, and its resilience. We first tested it with several prototypes and are now seriously going about using PTFE in and on buildings. Initially, it seems suitable as a second outer skin, for example as sun or heat protection.

Back in 2016 you teamed up with MDT-tex to create the exciting pavilion for the Amsterdam Light Festival: “The Eye Beacon”. The shape chosen for the Amsterdam project was inspired by the deep-sea world. What ideas drove the Frankfurt design?

Ben van Berkel: This is more strongly about the idea of tents. Moreover, the design is a bit of an homage to Richard Buckminster-Fuller. We wanted a degree of formal discipline, but also to highlight universal applicability. We wanted people to look at the pavilion and be able to imagine how such a system could be used on a facade.

In the immediate future, what opportunities are there for technical textiles as a construction material?

Ben van Berkel: Very many! These materials are now so incredibly tough and versatile. And they seem an obvious choice for the digital age – you can now, for example, weave LEDs into textiles. And the colors are as good as non-fading. Customary building materials can hardly keep up. We will probably first see technical textiles being used on facades, but they will soon also be deployed as construction materials I think.

Compared to conventional building materials, what is the difference when it comes to using technical textiles?

Ben van Berkel: What is so fascinating about these materials is that you can give them any shape you want – as the pavilion shows. They can be bent and molded at will, which creates completely new expressive opportunities for architecture. Architects may need to get used to this a bit. Sometimes industry is further advanced than we architects realize. Which is why it is always important to discuss things with manufacturers, to explore the possibilities a particular material affords.

How did the collaboration with MDT-tex come about?

Ben van Berkel: Both we and MDT-tex have for some time been conducting in-depth research in our respective fields. We had very similar interests as regards technical textiles, but completely different competences. We combined forces initially to conduct basic research together. Only in a second step did we address actual applications. We will now start testing the use of technical textiles in window and façade systems. I assume that in the next one or two years we will have reached a point where we will be able to bring the results to bear in one of our projects! For example, the conversion of traditional office builds into campus buildings for tech companies would be a key field to apply this type of façade solution.