Made to last forever

Tiles may just lie at our feet. Yet their material and appearance decisively influence how healthy and pleasant a room’s atmosphere is – so it makes sense to choose high-quality, environmentally-sound products. Based in Maastricht in the Netherlands Mosa, a firm with a history that stretches back over 136 years, has made a name for itself as a specialist for ceramic tiles. One reason for its continued success is undoubtedly that sustainable production is seen as part and parcel of company policy: “Sustainability has to be key for all elements at Mosa from raw materials to applied end products,” explains Dorien van der Weele, Sustainability Manager at Royal Mosa. And so much engagement for the environment does not go unnoticed: Specifically, almost the entire collection has earned the “Cradle to Cradle (C2C)” certification in silver, a standard which testifies to the biological and technical recyclability of the materials. Mosa is the first and only ceramic tile manufacturer in the world to gain this “Cradle to Cradle” Silver certification. The basic elements of Mosa’s sustainable concept include the reduction of waste, ensuring the high recycling potential of products by relying on natural materials, saving resources through renewable energy, an environmentally friendly water management system but also social working conditions.

Central circle

As a symbol of recycling, the circle is a central element for Mosa – currently, the team is working on perfecting the recycling system in construction: Through its nationwide campaigns the firm has for several years recycled remnants produced when tiles are cut by taking back and reusing such waste. The next step is to recycle all production waste such as the remnants of glaze and tile adhesive. This June Mosa tiles with a “Cradle to Cradle” certified adhesive were installed in the new building of the British School in Leidschenveen in the Netherlands, meaning circular construction is a step closer. Moreover, the company is working on additional pioneering ideas such as a leasing system for entire facades, floors and walls that can be returned to Mosa as part of a deposit system. Mosa is also very interested in supporting more detailed documentation of the materials used in a building, an EU-funded BAMB project (Buildings as Material Banks) funded by the EU, which awards the materials employed in a building an electronic “passport” as evidence of their sustainability with a view to improving materials’ recycling value. This would mean being able to call up information on the composition of the tiles, for example, for each and every building and therefore being able to determine how easily their materials can be recycled. “It is about handling resources responsibly,” explains Joy Moonen, Corporate Communication Advisor at Mosa.

Virtual and real

From Maastricht the tile specialist delivers its products to 50 countries and also offers architects and clients a service toolbox: from the design via prefabricated solutions through to a digital tool like the “Mosa Pattern Generator”: With this software it is possible for every project to select patterns for walls and floors in which all the available formats, grids, textures and colors of Mosa tiles are employed. Subsequently, the selected result can be imported to design and construction software programs. Moreover, with the “3D Tile Viewer” it is possible to see the details of the tiles from the pattern of the relief to the respective thickness so that it is almost as if you were actually holding them. And using the state of the art Augmented Reality App “Mosa Viewer” the desired product can be projected directly into the room for an ideal visualization. In addition, Mosa organizes regular training seminars for architects and interior decorators, for example with Dorien van der Weele, Manager Sustainability at Mosa. “We not only want to offer a product but also provide architects, planners and clients with a comprehensive service,” explains Moonen.

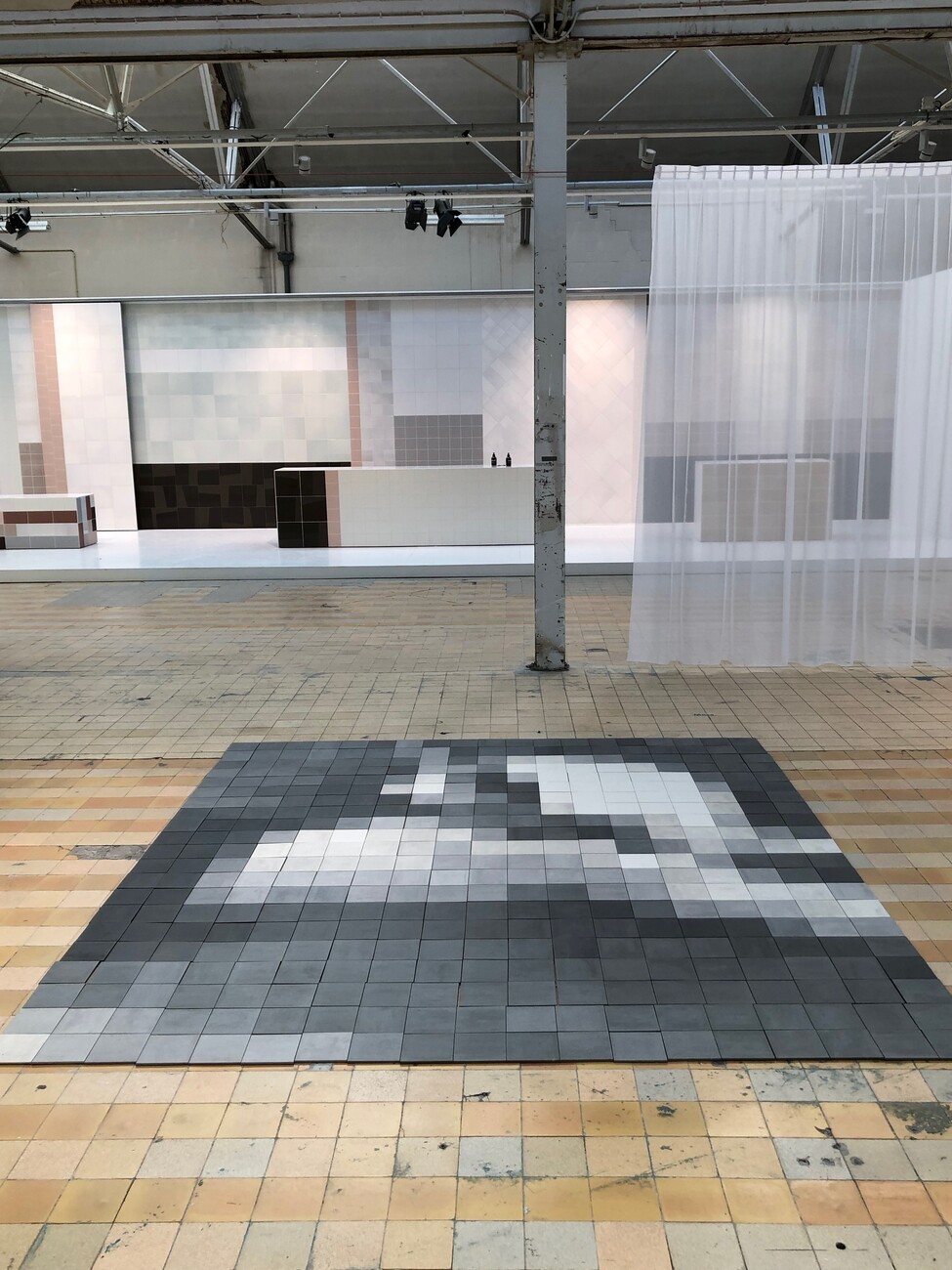

Moreover, the spacious design studio in Maastricht offers an opportunity to experience the signature surfaces first hand: Today the future resides in the halls of the former porcelain factory that marked the start of Mosa’s success story in 1883: The bright rooms on the first floor showcase the entire collection for walls, floors, facades and terraces. And all the options for individual projects can be tried out here using the samples. Numerous installations also provide ideas for further potential combinations. The fact that ceramic tiles by Mosa can also be transformed into art is also demonstrated in the exhibition through the artwork “Plongeon” by Noemi Sjöberg. In the original 22.20 meters long and 3.60 meters high the artist drew her inspiration from the tile models “Scenes”, “Global” and “Softgrip”: Beginning with a photograph from the 1920s of a swimmer she created an abstract Pixel puzzle with the tiles by Mosa whose original image becomes apparent from a certain distance. The artist assembled the mural comprising 3552 tiles in the design studio before it was transported to Paris this summer and installed under the bridge Pont du Garigliano crossing the Seine.

Dynamic and one of a kind

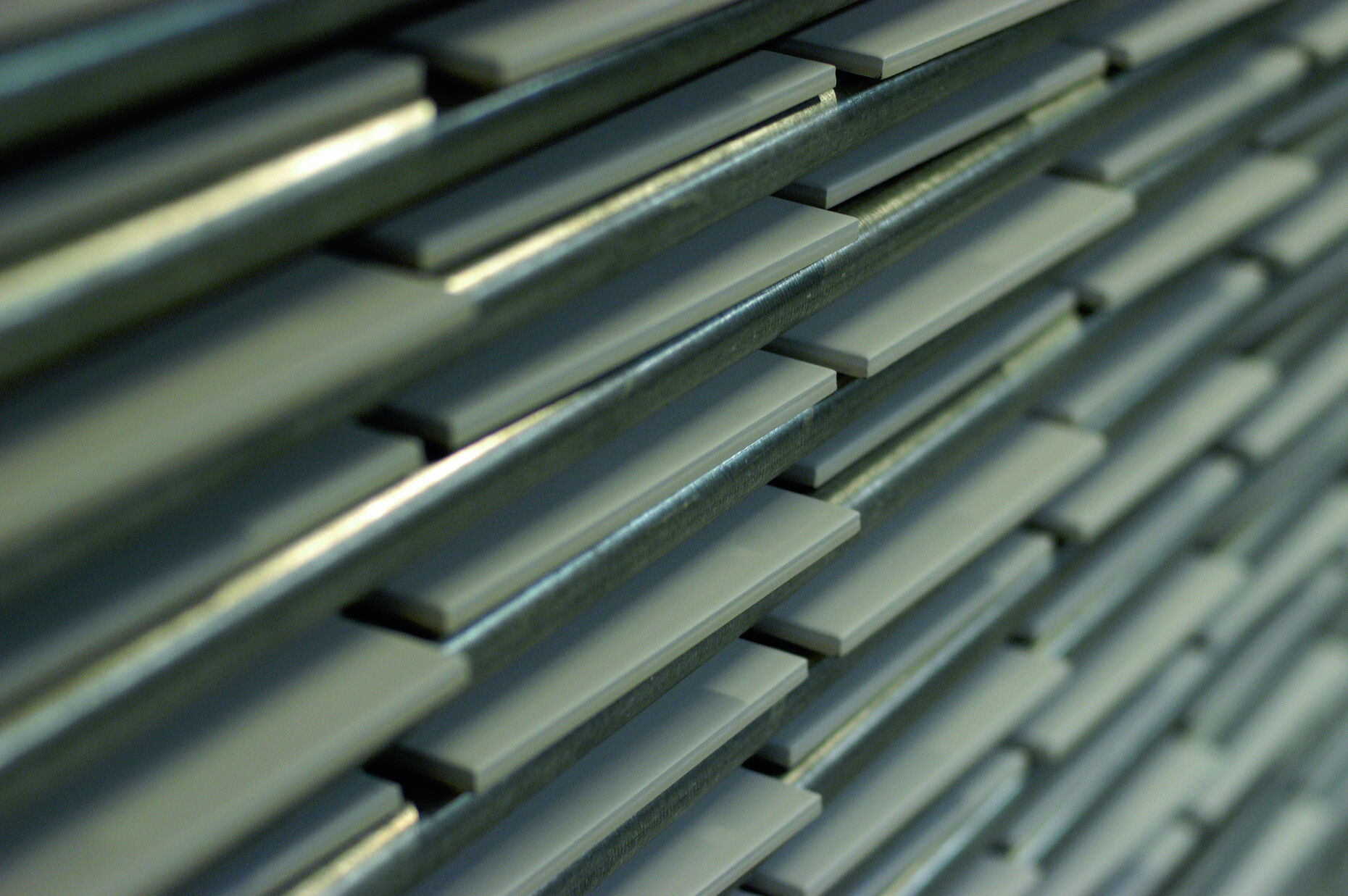

Just like the art mural every Mosa tile is also unique in its appearance: “The random variation produced by the spray granulate lends the tiles a visual vibrancy. Every tile is different and yet produces a cohesive appearance in combination with others,” explains industrial designer Mireille Meijs. Through the variation of fine and coarse ceramic whiskers the appearance of the texture can be influenced without altering the pleasant feel. Every tile and collection is unique – for example, “Quartz” has a textured relief featuring crystal-like particles, while in “Terra Maestricht” the product gets its unusual pattern through the fineness of the more cohesive powder. When it comes to individuality in colors there is a range of 32 shades available. The fact that a dynamic vibrancy can also be achieved with neutral, natural nuances is demonstrated by the “μ-series”: Depending on the incidence of light the mixture of tiny vibrant ceramic pigments in various colors produces a changing effect and a visual depth. Mosa aims at immense variation for individual projects but does not aim to be trendy: "We only launch a tile when we are convinced that it is perfect in every respect,” says Mireille Meijs, industrial designer at Mosa.

Anyone who has visited the Mosa factory in Maastricht is quick to notice how seriously the company takes its aim at perfection, because every tile is subjected to numerous testing stations before being released. Humans and machines alternately scrutinize every single product to ensure it is flawless from the still raw, pressed form of loam and sand through to the result after the double firing which produces a particularly high-quality glaze. Valuing craftsmanship and a deep passion for ceramics are two aspects that characterize the look and feel of Mosa products and gives the floor surface itself an extra dimension. The quality of Mosa's tiles and the wide range of services for architects, designers and planers can be experienced for example on 4 and 5 December 2019 at the upcoming Architect@Work in Düsseldorf.