SUSTAINABILITY

Stick, twist – live

It is not only Japanese architect Shigeru Ban who builds using paper, pasteboard and cardboard. With its Wikkelhouse Dutch company Fiction Factory is adopting an innovative approach for an ecological, environmentally friendly residential building made of corrugated cardboard. The mold-wrapping technique from which it derives its name in fact makes for great stability. A layer of wood and one of a waterproof but breathable foil additionally protects this creative construction from wetness and damp. From the paperboard to the adhesive, the raw materials used are exclusively renewable, thus making the building completely recyclable. The Wikkelhouse has already received a major accolade in the guise of the German Sustainability Award and German Federal Ecodesign Award. Starting with the way it is produced, and extending to the reusability of its robust modules and the recycling of its individual building components, the entire lifecycle of a Wikkelhouse thus conforms to the basic principles of sustainability. According to the Wikkelhouse team, the concept is three times as environmentally friendly as classic construction methods. The company is currently honing the idea so as to transform the Wikkelhouse into a 100-percent biodegradable home.

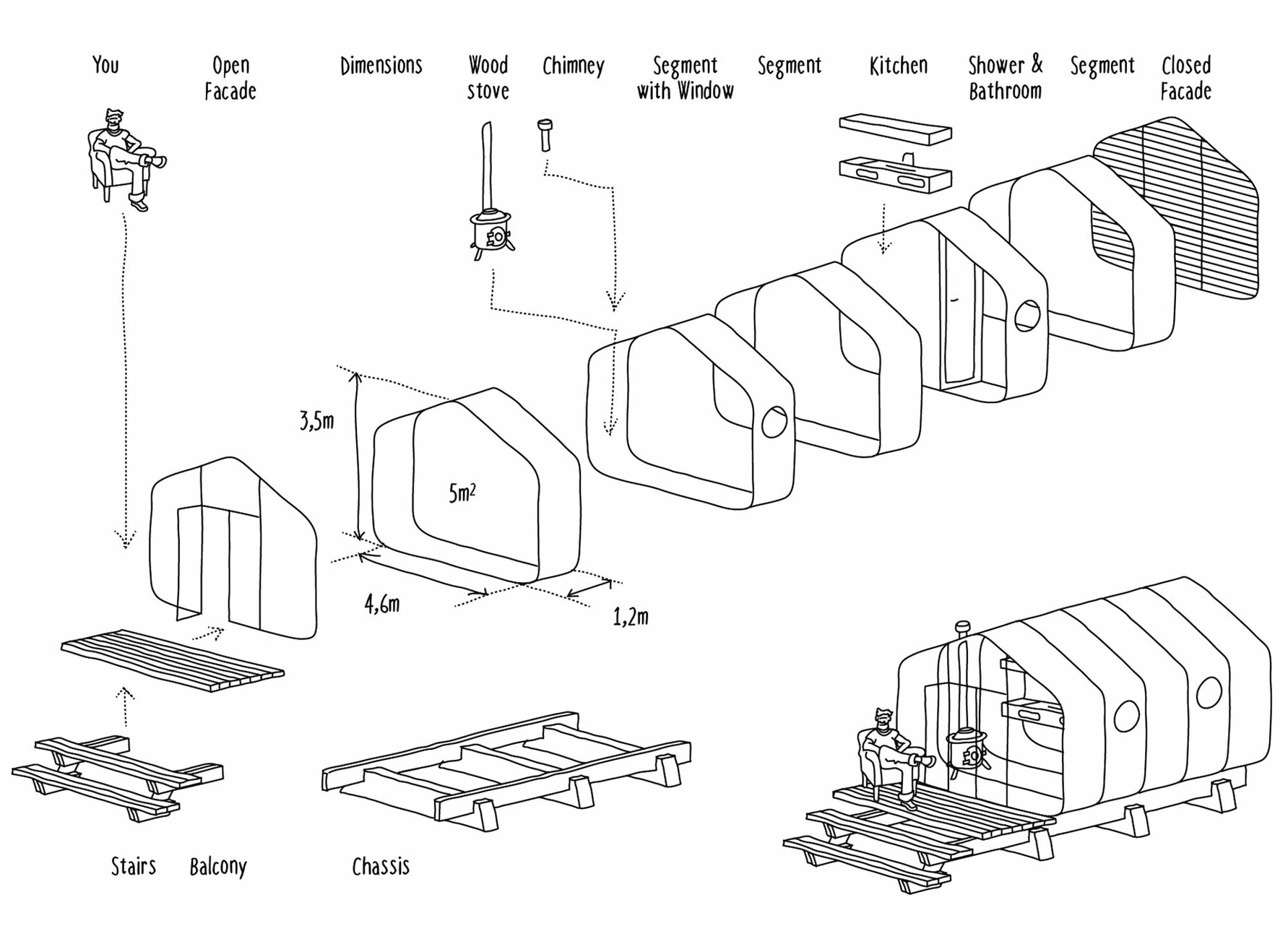

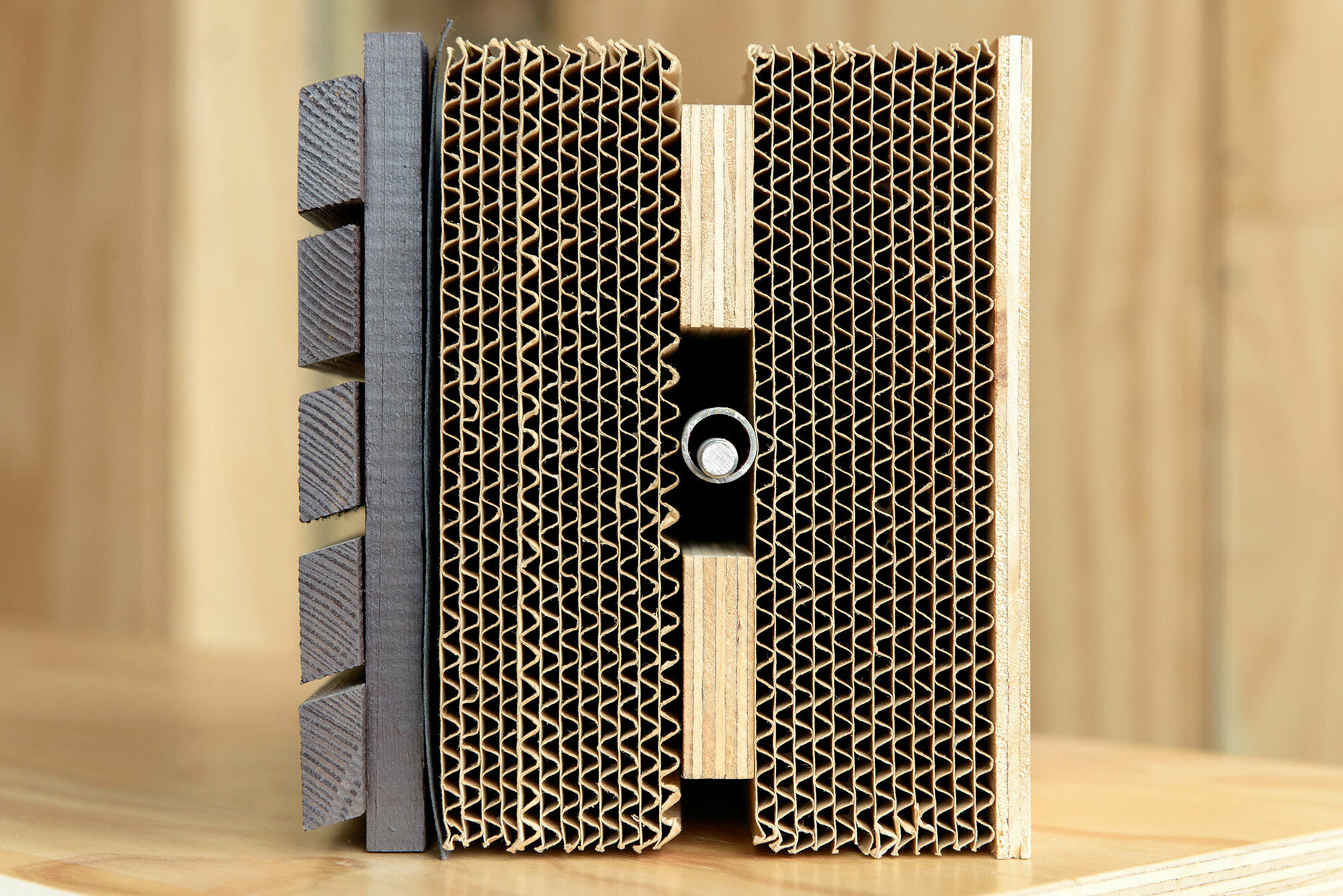

From a tiny house measuring 15 m² all the way to a long tubular residential unit, the Wikkelhouse can be adapted flexibly to individual requirements. Its possible uses remain open – from residential, garden or holiday home, study or playroom, accommodation for guests all the way to a houseboat or even a trade fair stand – anything is possible. All the elements of a Wikkelhouse consist of a total of 24 layers of corrugated cardboard, each of which is wrapped around a mold and glued in such a way that all the walls are dimensionally stable. 1.2 meters in thickness, 4.6 meters in length and 3.5 meters in height, each module weighs 500 kilograms and defines a five-m² area which can be combined with other segments to suit individual tastes.

Completely clad with wood, the interior of the house structure is reminiscent of a mixture of a boat building and mountain hut. Cooking and sanitary facilities can be supplied as smart home segments, the front modules can be ordered both glazed and as nontransparent sections. With its standardized, prefabricated elements, this lightweight structure does not need expensive foundations but is put together on a platform to make a finished residential house. According to the manufacturer, it takes only one day to erect – a construction time unrivaled in its shortness. A minimum durability of around 50 years is promised.

Fiction Factory’s Oep Schilling, who is based in Amsterdam, discovered the wrapping machine in 2012 and was “absolutely thrilled” with it. Originally built for paper wrapping it now manufactures prefabricated elements made of paperboard. “So far we have produced around 100 Wikkelhouses,” explains Schilling and the company supplies not only inside the Netherlands, but also to Belgium, Luxembourg, France, Germany, Great Britain, Scandinavia and Chile. Three elements cost 30,000 Euro plus transport. Interested parties can test living in a Wikkelhouse on a trial basis in various locations, for instance, right by the sea in Oudrop, at the Domaine de la Résidence in Metz, France, or on the island of Helgoland. Of course, certain architectural details such as the finish on the glazed front and its doors and the shape of the gabled roof with its curves could do with some refinement so that the Wikkelhouse looks less mainstream. However, with more quality in terms of design and stylistic vocabulary it really does have potential.