Sustainability

The joy of meeting again

“If you sail round the world in a boat, you recognize what ‘limited’ means, because there is simply nothing more than what you have with you. When I was back on land, I noticed that our global economy functions the same way,” Ellen MacArthur often recounts in one of her many appearances. The British women set a new record at the age of 24 for sailing single-handed round the world and on the basis of her insights established the not-for-profit Ellen MacArthur Foundation – which is today one of the leading institutions as regards the circular economy. The circular economy concept, though, had its origins in the 1970s, when the Club of Rome formulated "The Limits to Growth" and the green movement emerged. It has not until now, given the threat of a climate catastrophe and the scarcity of resources, that people are deciding not to simply consume and then throw things away, but instead to recycle materials and products.

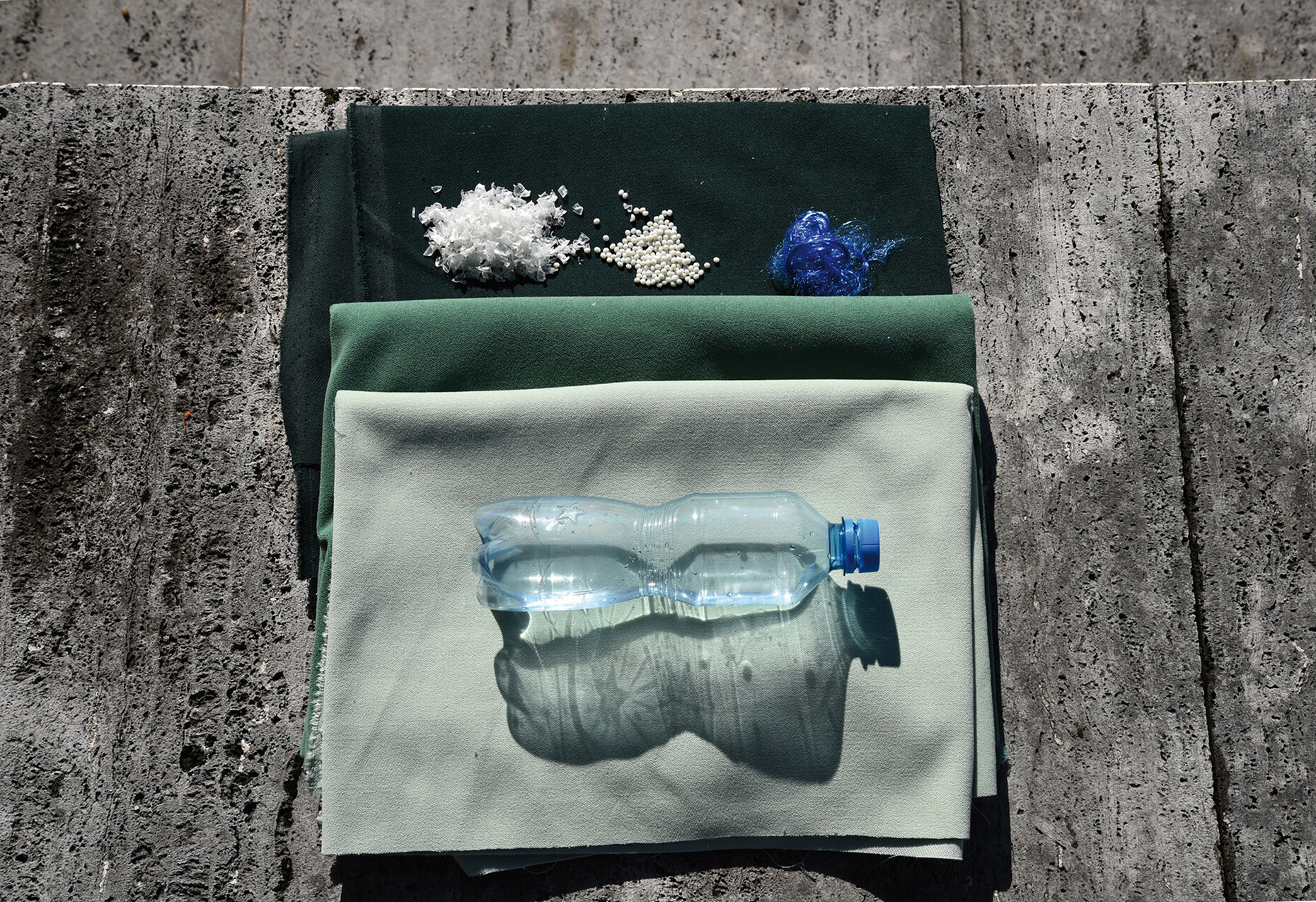

“Reduce, Repair and Recycle” is the motto in order initially to avoid waste and as a next step create something new from waste. Precisely as regards recycling most recently a massive number of materials, products and the related processes and services have emerged. Above all, the textile and fashion industry, which are especially in the focus of criticism owing to Fast Fashion, have responded to this. For a good 20 years, large volumes of waste PET bottles, plastic waste and fishing nets from the oceans have been collected and recycled. “Econyl” by Italian supplier Aquafil is one of the best-known polyamides used by fashion brands such as Adidas, La Perla and Triumph. The company also works for the carpet industry which had of late increasingly prioritized recycling: In its new recycling plant in Arizona it processes old floor coverings. The polypropylene thus obtained is then recycled in the injection-molding industry, calcium carbonate for road and building construction as well as Nylon 6 (polyamide) for textiles and products. Thus, for example, Object Carpet uses “Econyl” for its latest carpet collection Velaa.

In the press

Another method if to break plastic and textiles down and press them in order to create panels – partly with the addition of artificial resin. This method is used, for example, by Really, the joint venture between Kvadrat and couturier Klaus Samsøe, who seeks in this way to exploit the mound of waste fabric left behind by fashion producers and laundries. The boards Really makes from recycled cotton and wool can be processed with the customary wood-working tools and can in fact even be bent. Really is already to be found in furniture stores such as Brunner – the boards are even suited for the contract world. Tyrol’s Tante Lotte Design follows the same principle, pressing the “waste product” (wool that is too coarse to be used for clothing) left over when breeding sheep to form its “Whisperwool” acoustic panels. De Vorm in the Netherlands takes a similar approach, although for its furniture made from formed nonwovens it relies on old bottles made of PET plastic. As is the case with the market leader among the material suppliers Becker Brakel, De Vorm uses heat to three-dimensionally shape the panels – the maker boasts that “Pod”, its high-back armchair designed by Benjamin Hubert, is the world’s largest 3D-shaped nonwoven shell.

Bringing production full circle also means creating a product that can in turn be recycled. Bolon has given this some thought; it installed its own recycling plant back in 2014 where it processes the production residues for the backings of its PVC carpets. Now it is intending to boost the 33-percent recycled materials content of the carpets to 50 percent by using post-consumer waste – however, the majority of such waste is not suitable. Which is why Bolon has set out to design its own product in such a way that it can itself be easily recycled: Using the new NoGlue strip, the floor covering can simply be re-laid or moved without glue residues complicating recycling. Bolon introduced NoGlue in 2018, and in 2020 it intends to take receipt of its first carpets for recycling. The company is working on a leasing service for the NoGlue carpets.

Waste is considered a raw material outside the textile and textile-related industries, too: In the case of “Corcrete”, Studio Niruk takes waste cork and mixes it with concrete to create highly aesthetic and very light concrete panels that even dampen noise. Print Your City! uses 3D printing to recycle plastic waste into benches for public spaces. Nendo is currently presenting the "N02 Recycle" chair for Fritz Hansen, whose seat shell is made from recycled household waste. The "Ocean Chair" by Mater and "S-1500" by Snøhetta in cooperation with Nordic Comfort Products are made of old fishing nets and recycled steel. Magna Glaskeramik turns old glass from industrial glass and bottle production into granulates that are then mixed with various additives to produce panels which are sintered using a patented process: heat turns them into rigid panels. The glass ceramic panels can be used for interiors, furniture or even as façade cladding. The crystalline look, and it can be back-lit, too, creates a very special effect, something Sebastian Herkner has exploited for his “Font” side-table for Pulpo.

Closing the gaps

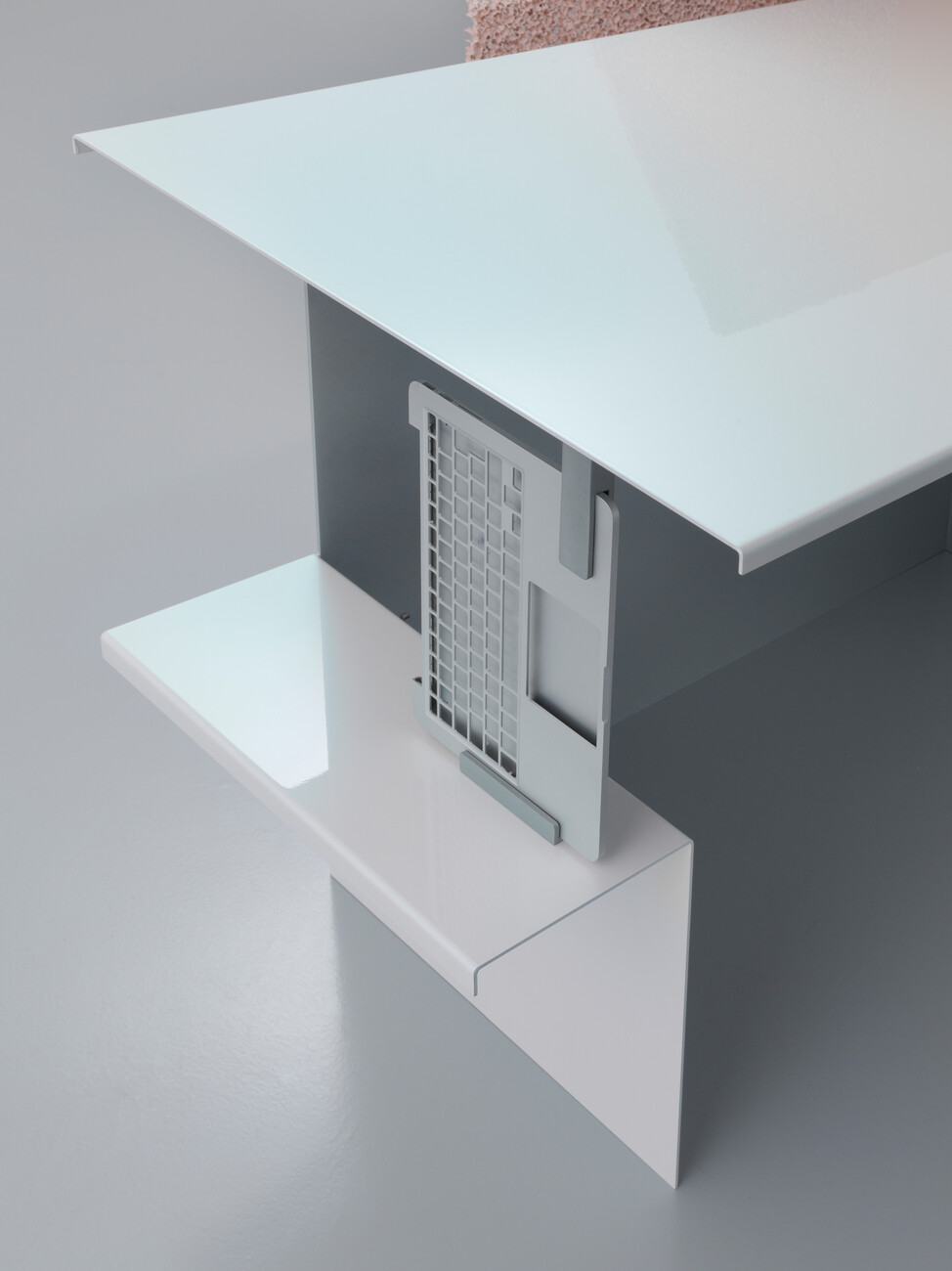

Recycling tends to rely on energy inputs and a chemical process; it’s therefore more eco-friendly simply to re-use materials or objects. Young designers such as Andrea Trimarchi and Simone Farresin at Formatfantasma do just this – as part of their two-year “Ore Streams” project they created furniture re-using electronic waste requiring minimal inputs.

With their UMAR project for the NEST facility in Dübendorf, Switzerland, researchers Dirk Hebel and Felix Heisel and engineer Werner Sobek are currently exploring how the circular principle can be applied in architecture. For the UMAR (“Urban Mining and Recycling”) housing unit only single-origin materials and inserts are used, meaning it can be re-used. The window glass is held in place mechanically and not with silicone, for example. The Lindner heating or cooling slab also feature single-origin components. A series of already recycled construction materials such as Magna Glaskeramik and Smile Plastics were utilized, panels of pressed, shredded plastic cutting boards with a grain that resembles marble. The Dutch company Stonecycling is especially smart clever: Its “Waste Based Bricks” are held in place not by mortar but threaded onto the reinforcing steel. And the façade is decorated by copper panels from a hotel in Austria. After five years UMAR’s time will be over and the individual components used for something new. Felix Heisel, one of the project initiators, hops that the gap between producers and consumers will be closed in order to transition from a linear to a circular economy. All these examples go to show that the ball is rolling in the right direction.